Modifications

Overview

Modifications

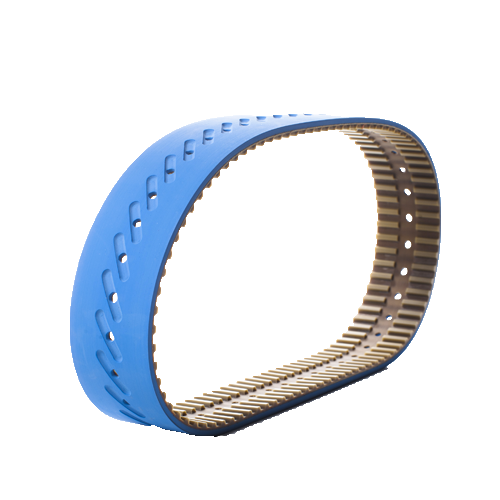

Process enhancements, skilled personnel, a can-do attitude and ongoing capital equipment investments enable Megadyne to stay at the forefront of new design developments and solution delivery to customers across the spectrum of industries we serve. In addition to materials and process selection of the base belt, Megadyne can fully customize our belts with the following machined modifications:

- Holes/Perforations

- Custom shapes

- Slots

- Tooth removal

- Grooves

- Back grinding

- Vacuum Countersinks

- V-guides

Ask to our OEM team for find your solution.