Material Handling

Material handling solutions

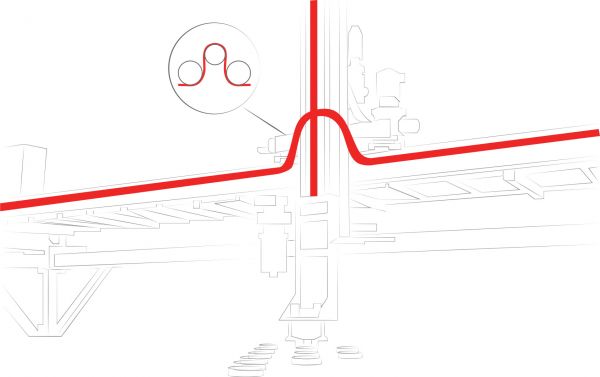

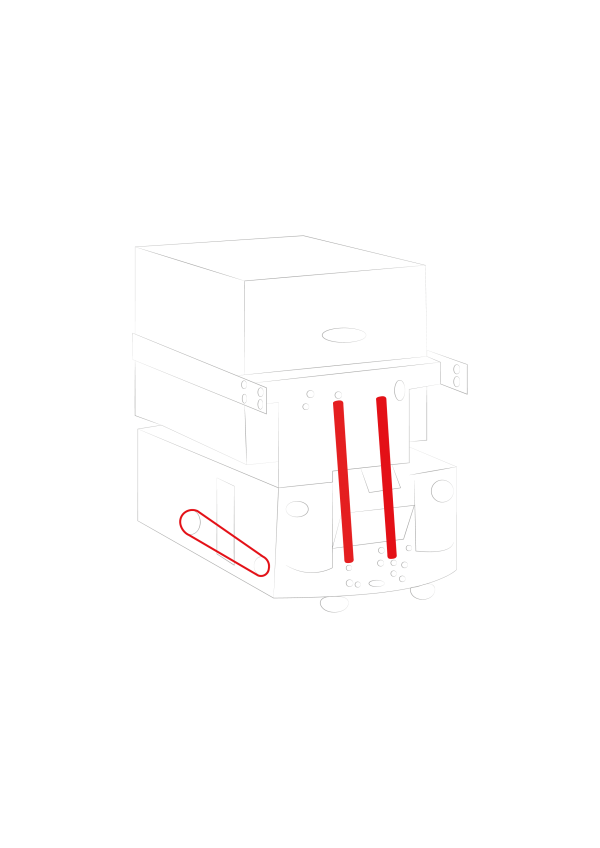

Gantry Robot

Gantry Robot

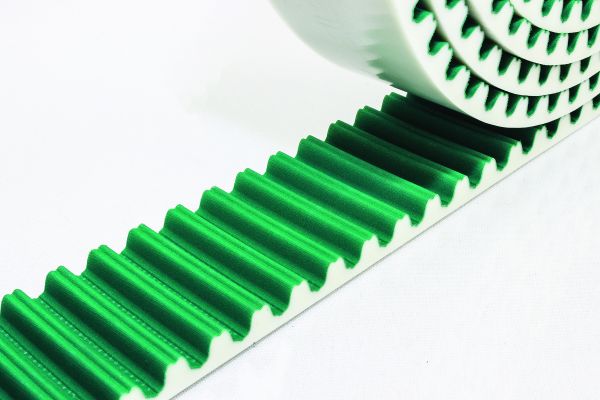

Megalinear

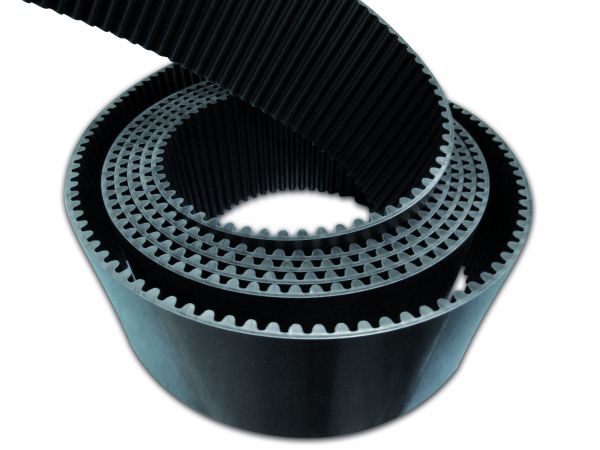

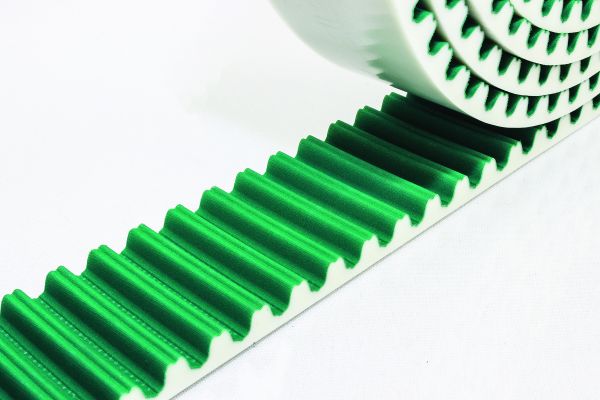

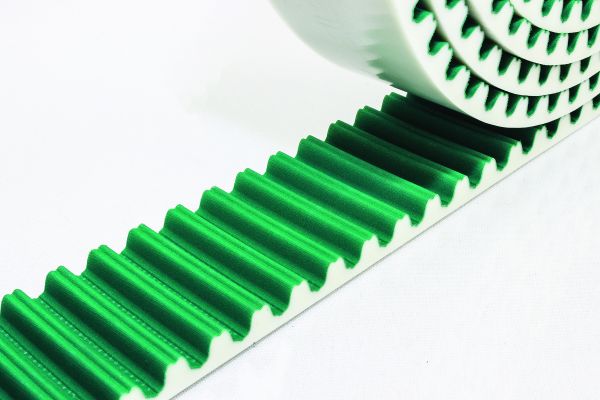

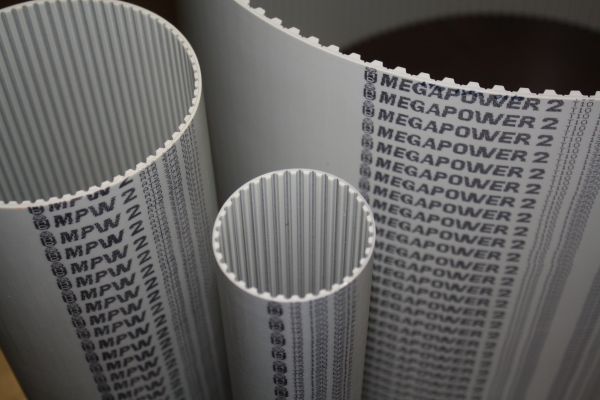

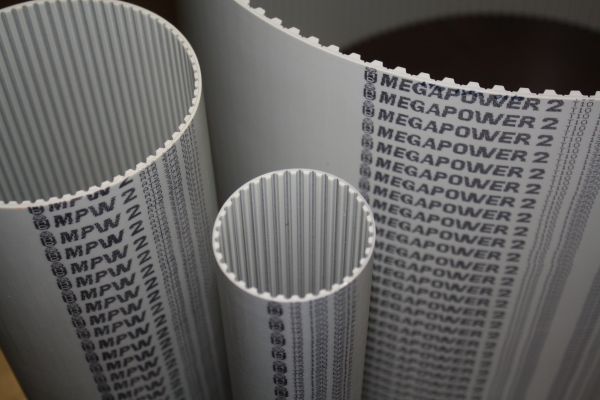

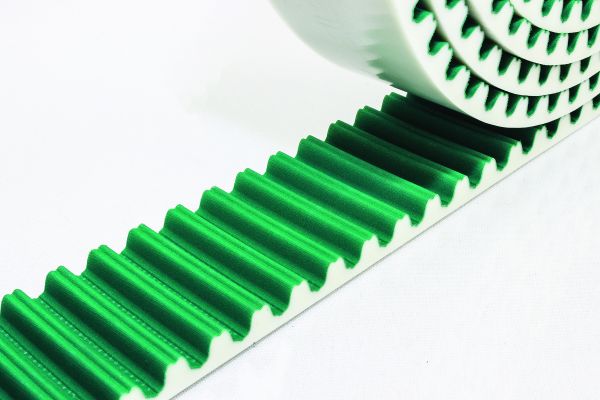

Thermoplastic PU belts, 92 ShA, supplied as open length rolls or as endless jointed belts; available in various tooth designs and cords.

Recommended pitches: MTD14, RPP14 XHP, AT20

- Constant dimension and length, improved accuracy

- Maintenance stop reduced during working time

Megalinear GW

High-performance thermoplastic polyurethane timing belts with steel zinc coated cords.

Available pitches: 14M and 20M

- High transmittable power under continuous substantial loads

- Greater breaking strength

- High tooth resistance

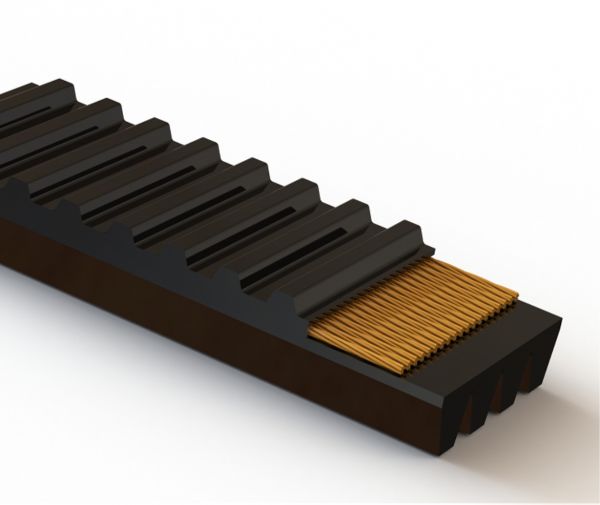

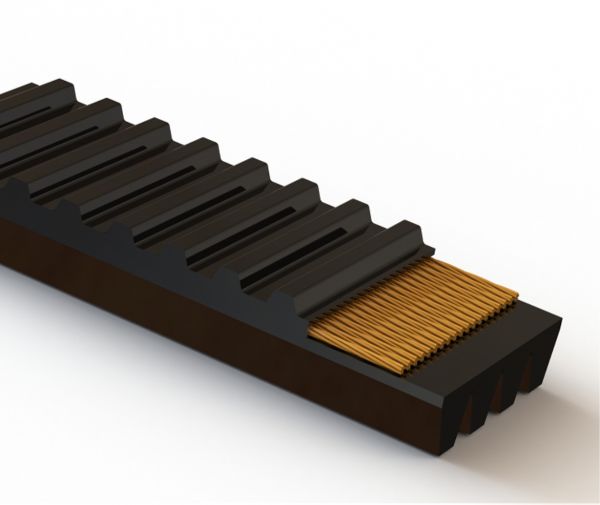

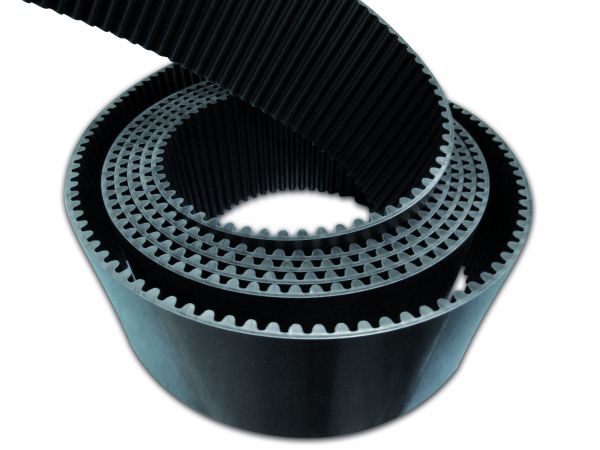

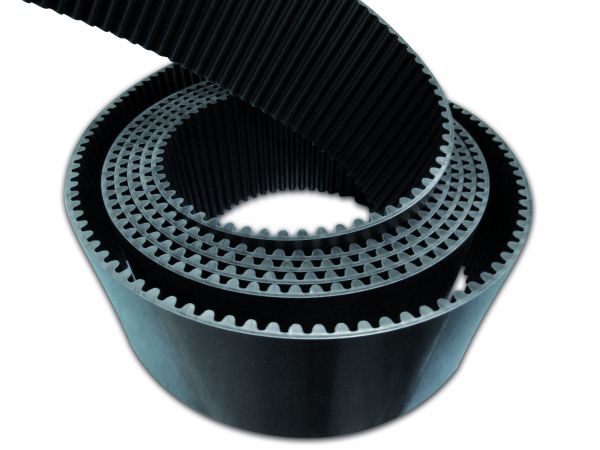

Rubber open end timing belts

Rubber base timing belts coming from sleeves for spiral cut belts and from press for straight cut belts.

Recommended Pitch: RPP14 (Steel cords)

- Very limited elongation

- Maximum traction load capacity

Pulleys

- Available cast pulleys or from laminated material in metal

- Standard or special profile custom made

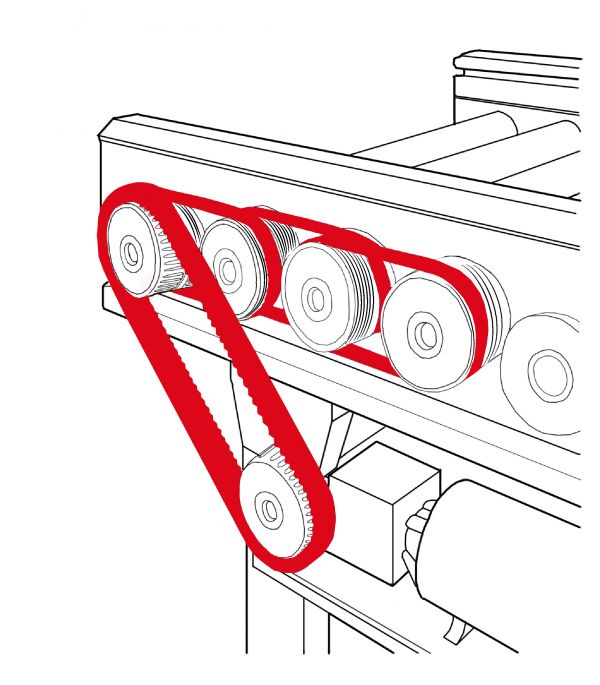

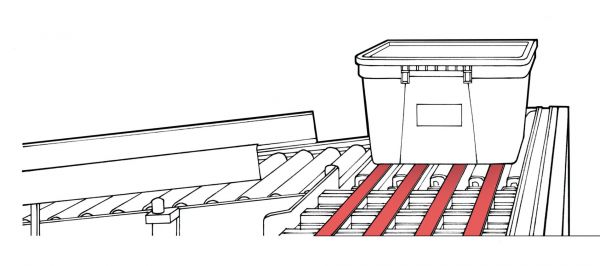

Roller Conveyor Applications

Roller Conveyor Applications

Timing belts or poly-v rib belts are commonly used on roller conveyors. On the external side of the roller, power transmission belts deliver power from the motor to the main driven conveyor roller. From this stage rollers are interconnected by either timing belts or poly-v rib belts, some of which can be produced with elastic-stretch properties.

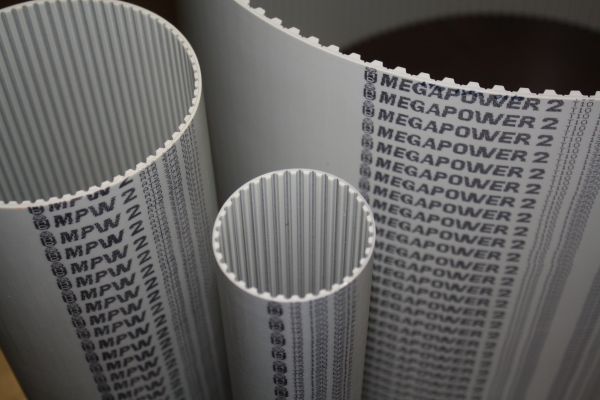

Megapower 2

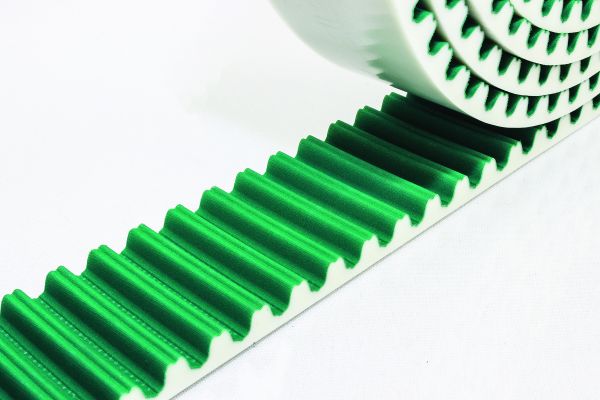

Truly endless belt manufactured in thermoset polyurethane 85 ShA with high strength helically zinked steel cord.

- High positioning precision and excellent dimensional stability

- Constant and high angular speed

- Superior wear and abrasion resistance

- Maintenance free

PV rubber ribbed belts

Endless belts with longitudinal V-shaped grooves which combine the benefits of flat belts and V-Belts. Supplied with standard or elastic cords.

- High flexibility

- Improved power performance by increasing the number of ribs

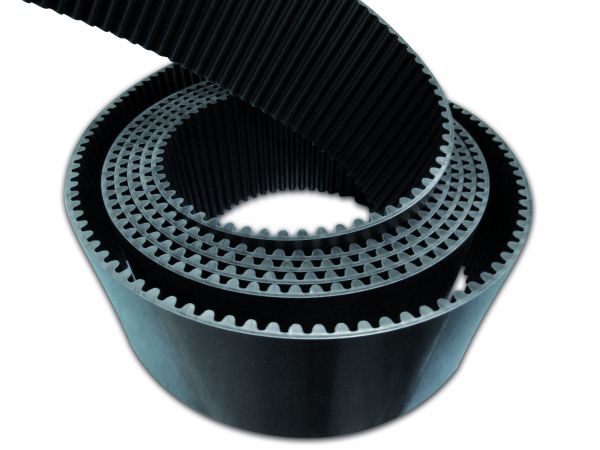

Rubber endless timing belts

Rubber Endless Timing belts made of high-quality rubber compounds, and high-performance tension members.

- Molded to length and pitch designation

- High performance

- Low noise

Megadyne rollpower

Elastic ribbed rubber belt designed to outperform on roller conveyors.

- Stable tension over time

- Smooth, reliable and quiet running

- Long life expectancy

- Speed up to 3 m/s

- Easy to install and replace

Pulleys

- Available cast pulleys or from laminated material in metal

- Standard or special profile custom made

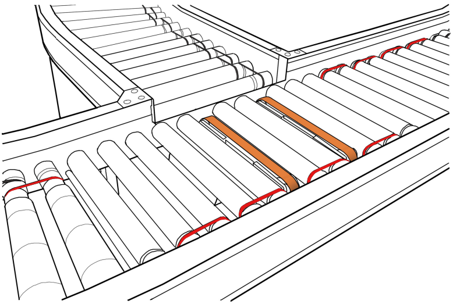

Diverters

Diverters

In today warehousing and distribution environments, offloading of product for specific fulfillment needs can be accomplished with high friction belts right angle diverters. Starting with a base synchronous belt, we offer a broad range of high friction cover surfaces. From Megalinear joined polyurethane synchronous belts and Megaflex truly endless polyurethane synchronous belts with TPU smooth covers, to rubber with homogeneous covers, along with specialty cover materials like DuraTaq high friction.

Rubber endless timing belts

Rubber Endless Timing belts made of high-quality rubber compounds, and high performance tension members.

- Customized with special covers (DuraTaq™ and Linatex®)

- Good grip

Polyurethane timing belts

Truly endless or joined timing belts with thermoplastic polyurethane with high strength helically wound zinc coated steel tension members.

- Customized with special covers used to divert goods 90° from the starting direction of travel.

- Low elongation and high stability

- High friction and wear resistance.

Megaweld

Thermoplastic PU belts with different hardnesses and custom cross sections.

- High flexibility and grip

- Excellent resistance to aging and abrasion

Megadyne rollpower

Elastic ribbed rubber belt designed to outperform on roller conveyors.

- Stable tension over time

- Smooth, reliable and quiet running

- Long life expectancy

- Speed up to 3 m/s

- Easy to install and replace

Long belt lifetime

High-resistance Natural rubber coating with double the abrasion resistance than Linatex

Increased lifetime load

Industrial Elevators / Industrial lift system

Industrial Elevators / Industrial lift system

Megalinear P3.3

Thermoplastic Flat PU belts, 92 ShA, supplied as open length rolls or as endless jointed belts with steel cord.

- Operating in a wide variety of environments

- Space-saving

- Reduced elongation under load

Megalinear

Thermoplastic PU belts, 92 ShA, supplied as open length rolls or as endless jointed belts; available in various tooth designs and cords.

Recommended pitches: MTD14, RPP14 XHP, AT20

- Constant dimension and length, improved accuracy

- Maintenance stop reduced during working time

Megalinear GW

High-performance thermoplastic polyurethane timing belts with steel zinc coated cords.

Available pitches: 14M and 20M

- High transmittable power under continuous substantial loads

- Greater breaking strength

- High tooth resistance

Pulleys

- Available cast pulleys or from laminated material in metal

- Standard or special profile custom made

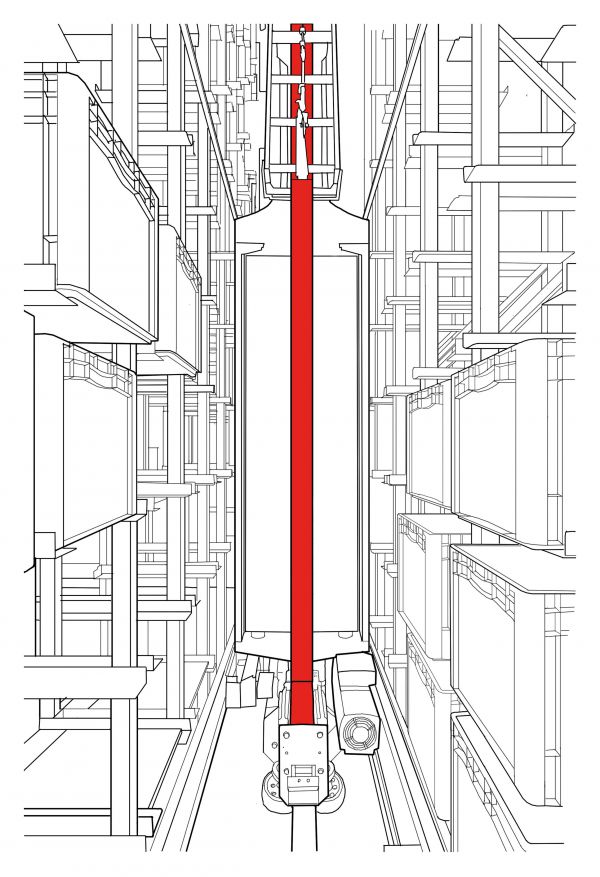

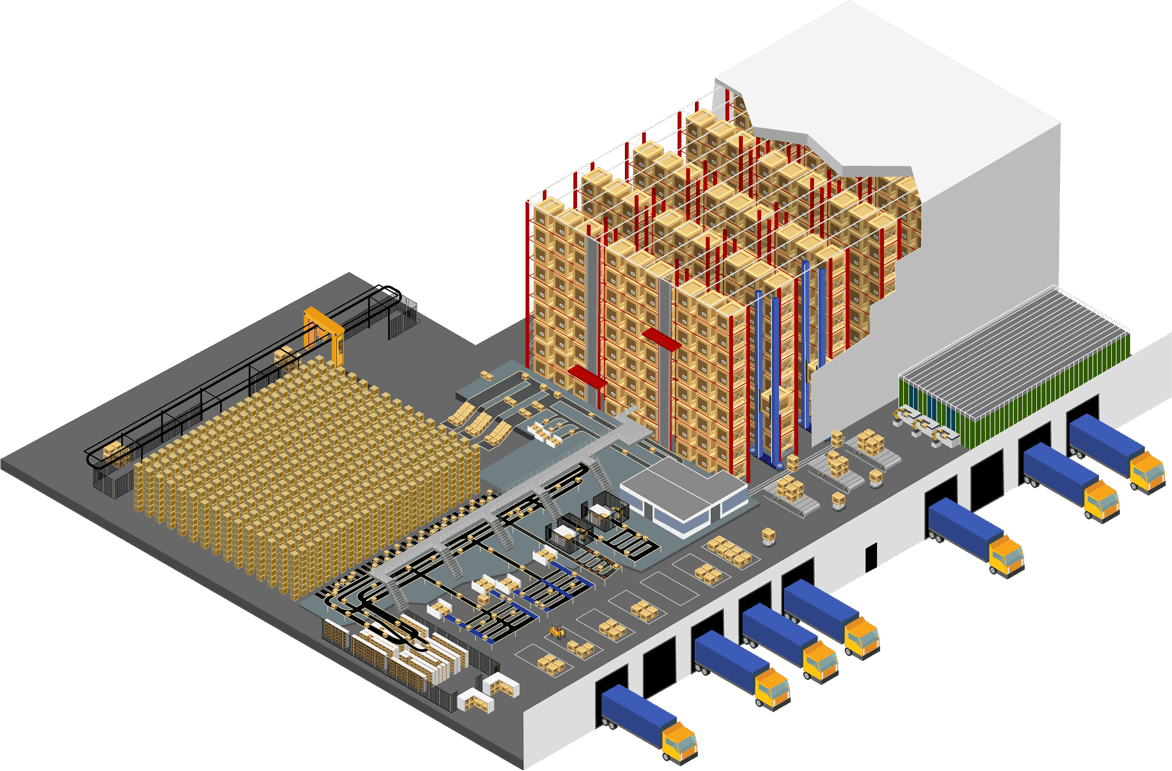

AS/RS

AS/RS

Megalinear

Thermoplastic PU belts, 92 ShA, supplied as open length rolls or as endless jointed belts; available in various tooth designs and cords.

Recommended pitches: MTD14, RPP14 XHP, AT20

- Constant dimension and length, improved accuracy

- Maintenance stop reduced during working time

Megalinear GW

High-performance thermoplastic polyurethane timing belts with steel zinc coated cords.

Available pitches: 14M and 20M

- High transmittable power under continuous substantial loads

- Greater breaking strength

- High tooth resistance

Megalinear QST

Open-end Polyurethane Timing belts, self-tracking due to the offset helical tooth design.

Available pitches: 8M and 14M

- High torque capacity

- Low noise

- Positive engagement in Bi-directional lift applications

Rubber open end timing belts

Rubber base timing belts coming from sleeves for spiral cut belts and from press for straight cut belts.

Recommended Pitch: RPP14 (Steel cords)

- Very limited elongation

- Maximum traction load capacity

Special low temperature compound

RCS/RS - AVS/RS

RCS/RS - AVS/RS

Rubber endless timing belts

Rubber Endless Timing belts made of high-quality rubber compounds, and high-performance tension members.

- Molded to length and pitch designation

- High performance

- Low noise

Megapower 2

Truly endless belt manufactured in thermoset polyurethane 85 ShA with high strength helically zinked steel cord.

- High positioning precision and excellent dimensional stability

- Constant and high angular speed

- Superior wear and abrasion resistance

- Maintenance free

Pulleys

- Available cast pulleys or from laminated material in metal

- Standard or special profile custom made

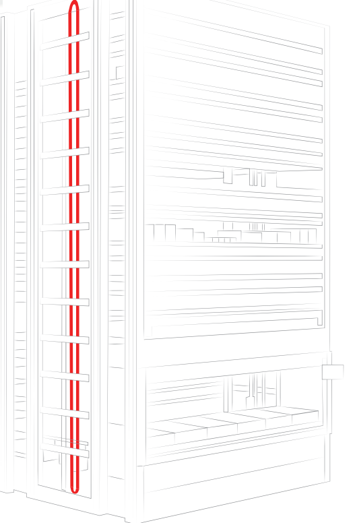

Vertical Lift modules

Vertical Lift modules

Megalinear

Thermoplastic PU belts, 92 ShA, supplied as open length rolls or as endless jointed belts; available in various tooth designs and cords.

Recommended pitches: MTD14, RPP14 XHP, AT20

- Constant dimension and length, improved accuracy

- Maintenance stop reduced during working time

Megalinear GW

High-performance thermoplastic polyurethane timing belts with steel zinc coated cords.

Available pitches: 14M and 20M

- High transmittable power under continuous substantial loads

- Greater breaking strength

- High tooth resistance

Megalinear QST

Open-end Polyurethane Timing belts, self-tracking due to the offset helical tooth design.

Available pitches: 8M and 14M

- High torque capacity

- Low noise

- Positive engagement in Bi-directional lift applications

Rubber endless timing belts

Rubber Endless Timing belts made of high-quality rubber compounds, and high performance tension members.

- Customized with special covers (DuraTaq™ and Linatex®)

- Good grip

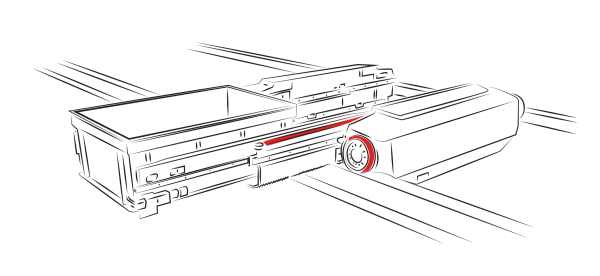

Shuttle

Shuttle

Megapower 2

Truly endless belt manufactured in thermoset polyurethane 85 ShA with high strength helically zinked steel cord.

- High positioning precision and excellent dimensional stability

- Constant and high angular speed

- Superior wear and abrasion resistance

- Maintenance free

PV rubber ribbed belts

Endless belts with longitudinal V-shaped grooves which combine the benefits of flat belts and V-Belts. Supplied with standard or elastic cords.

- High flexibility

- Improved power performance by increasing the number of ribs

Rubber endless timing belts

Rubber Endless Timing belts made of high-quality rubber compounds, and high-performance tension members.

- Molded to length and pitch designation

- High performance

- Low noise

Pulleys

- Available cast pulleys or from laminated material in metal

- Standard or special profile custom made

Increased lifetime, reduce transmission dimension, better performance

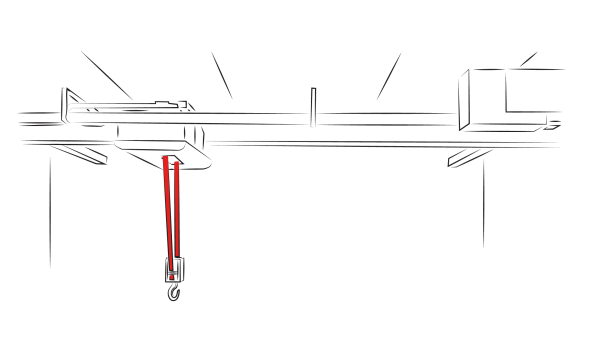

Belt hoist

Belt hoist

Megalinear P3.3

Thermoplastic Flat PU belts, 92 ShA, supplied as open length rolls or as endless jointed belts with steel cord.

- Operating in a wide variety of environments

- Space-saving

- Reduced elongation under load

Required a bigger drum

Constant maintenance and breakdown

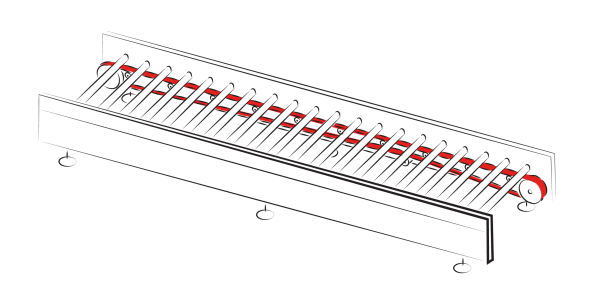

Live Roller

Live Roller

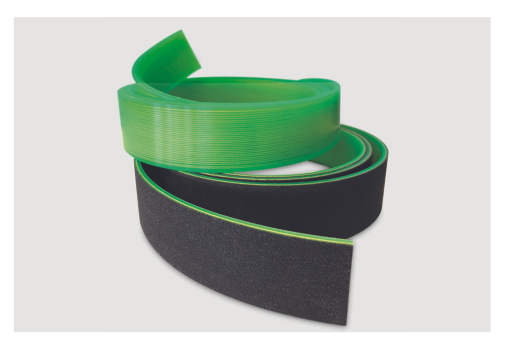

MEGALINEAR LIVE ROLLER (MLR)

MLR is a durable, reliable and low-maintenance engineered belt for extended life in demanding applications in a Logistics warehouse. In the realm of modern intralogistics, power transmission belt systems must meet rigorous criteria: reliability, durability, and efficiency. MLR-45 meets all of the criteria and more!

-

Flexibility ensures smooth item transfer on roller conveyors.

-

Made of polyurethane, available in green with or without an antistatic black fabric, balancing friction for efficiency.

-

MEGALINEAR MLR-45 optimizes friction, improving security and energy use.

Megalinear

Thermoplastic PU belts, 92 ShA, supplied as open length rolls or as endless jointed belts; available in various tooth designs and cords.

Recommended pitches: MTD14, RPP14 XHP, AT20

- Constant dimension and length, improved accuracy

- Maintenance stop reduced during working time

Pulleys

- Available cast pulleys or from laminated material in metal

- Standard or special profile custom made

Rubber endless timing belts

Rubber Endless Timing belts made of high-quality rubber compounds, and high-performance tension members.

- Molded to length and pitch designation

- High performance

- Low noise

Palletizer - Offloading and Delivery Conveyor

Palletizer - Offloading and Delivery Conveyor

Offloading & delivery conveyor

They are typically fitted with flat belts, however multiple path polyurethane timing and rubber belts with high friction covers are also common.

Special cover materials are available on belt used where accumulation occurs.

PU/Rubber timing

Rubber / Polyurethane joined coated timing belts to maximize grip and durability over time.

- Equipped with special covers

- High friction and wear resistance

Moulded rubber flat & synchronous

Rubber / Polyurethane Endless coated timing belts to maximize grip and durability over time.

- Equipped with special covers

- High friction and wear resistance

Overview

Material handling is integral in maintaining productivity, and it involves far more than handling inventory. It entails moving, storing, controlling, and protecting materials throughout their lifespan. Material handling takes place throughout every stage of a material’s life cycle from manufacturing, warehousing, and distribution to consumption and disposal. Material handling comes with many benefits, such as the ability to assist with forecasting, production planning, resource allocation, inventory management and control, delivery to consumers, and certain after-sales services. Megadyne’s extensive experience is crucial in the Material Handling market which is all about precise positioning and placement. With a broad portfolio of belt types, process capabilities and material options Megadyne belts are used in general conveying, specialty handling and high speed bi-directional lifting applications.

Material Handling Systems

Successful material handling systems require many different components to achieve efficient results. Material handling systems assist with sorting products in distribution centers. They are highly automated to optimize the productivity and efficiency of a variety of operations. Properly implemented and well-designed material handling solutions reduce operational costs and improve services for a wide range of businesses.

Megadyne's Material Handling Solutions

The experts at Megadyne continue to keep pace with the rapid developments in the material handling industry. As a result, we have expanded our selection of conveyor and polyurethane timing belts to meet this industry's specific requirements and overcome its various challenges. The latest in our line of top-quality products is Megalinear QST, which offers perfect tracking, positive drive, and minimal noise.

Applications that benefit from our innovative solutions include:

Automated Storage Retrieval System (ASRS)

Large Warehouse and Distribution centers use computer aided technology to move and store small and large goods being inventoried. Megadyne high strength synchronous belts are used in both single and double mast fixed aisle lift systems,as well as on gantry cranes and carousel systems.

Transport Platform

As part of the ASRS systems, transport platforms are used to shuttle the goods being stored from the lifting apparatus to the storage rack. Timing belts with high friction, wear resistant covers are used to telescope products into the dedicated storage location.

Offloading & Delivery Conveyors

Offloading and delivery conveyors are typically fitted with at belts, however multiple path polyurethane timing and rubber belts with high friction covers are also common. Special cover materials are available on belts used where accumulation occurs.

Diverters

In today's warehousing and distribution environments, offloading of product for specific fulfillment needs can be accomplished with high friction belt right angle diverters. Starting with a base synchronous belt, we offer a broad range of high friction cover surfaces. From Megalinear joined polyurethane synchronous belts and Mega ex truly endless polyurethane synchronous belts with TPU smooth covers, to rubber synchronous belts with homogeneous covers, along with specialty cover materials like DuraTaq® high friction.

Pallet Conveyor

Pallet Handling Conveyors are designed to move light to heavy loads in a precise, flexible manner. Used in warehouse picking and delivery systems or in assembly operations in a number of manufacturing environments. Starting with a base synchronous belt, we offer a broad range of high friction cover surfaces.

Roller Conveyor

Timing belts or poly-v rib belts are commonly used on roller conveyors. On the external side of the roller, power transmission belts deliver power from the motor to the main driven conveyor roller. From this stage rollers are interconnected by either timing belts or poly-v rib belts, some of which can be produced with elastic-stretch properties.

Products

Thanks to the wide range of customized and standard products in our selection, many customers trust the experts at Megadyne to provide them with the ideal material handling solution. Browse our current selection and select the right solution to meet your application's needs.

Timing Belts

We offer several timing belt options, including:

-

MEGASYNC™ SILVER3: a higher power rating of over 20% when compared to the former Silver and Silver2 belt range and a wealth of improved properties at the same price.

-

Open End RPP Steel: Open End RPP Steel offers superior performance with EPDM rubber along with durable steel reinforcement. It's ideal for use in many applications requiring sufficient chemical, abrasion, temperature, and wear resistance.

-

MEGALINEAR GW: This high-performance belt consists of thermoplastic polyurethane that withstands high-load applications.

Multi-Rib Belts

For applications in need of a multi-rib belt, we offer:

-

PV Rubber Ribbed: Our J, L, and M section multi-rib V belts work well in high-ratio and fast-paced applications. PV rubber-ribbed belts are capable of running at high speeds and offer enhanced flexibility. They feature polyester cords and polybutadiene rubber construction and are designed to perform high-ratio drives, minimize noise levels, and deliver minimal vibration.

-

Megadyne carries some of the best material handling equipment available. Regardless of your specific needs, we will help you find the right material handling solution. If you would like to learn more about our product offerings, contact us to talk to one of our experts.

Success Stories

-

Automatic Warehouse

-

Automatic Warehouse

In the logistics field, automated storage and retrieval systems (AS/RS) are the solution chosen by supply chain managers to maximize storage density and handle the increased amount of goods. Megadyne can provide a complete drive system meeting all the performance requirements of a modern AS/RS system. Read more ….