Accu-Link®

Overview

Accu-Link®

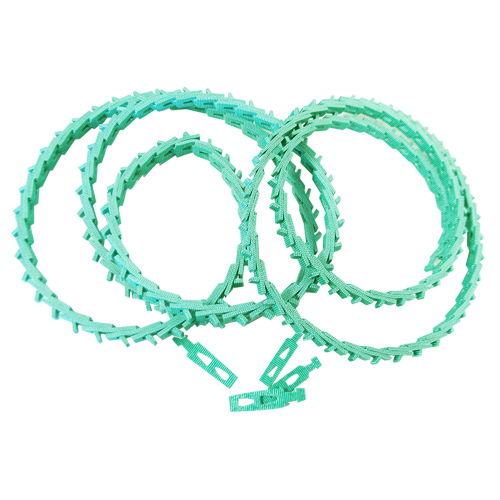

Constructed with wear and oil resistant urethane and reinforced with high strength polyester, todays Accu-Link® is designed to save labor and costs by offering easy installation on hard to get to v belt drives.

Supplied in open end form, where a short length of belt can be used to make many different belts lengths quickly and easily. Perfect for applications where drive vibration is a problem.

Features

The ideal substitute for conventional rubber V-Belts, Accu-Link® belts combine superior strength, durability and quick easy assembly to keep equipment up and running at the same running horse power ratings as rubber belts. Furthermore, Accu-Link® belts can have wide length variability simply by modifying the number of links.

Accu-Link® belts are manufactured with a revolutionary new process which creates smooth, precise side profiles on each link. Links are made with a polyurethane polymer reinforced by a multilayer woven polyester fabric.

Main components

Accu-Link® belts are manufactured with a revolutionary new process which creates smooth, precise side profiles on each link. Links are made with a polyurethane polymer reinforced by a multilayer woven polyester fabric.

Mechanical and chemical properties

- Flexible length adjustment, by modifying the number of links

- Reduced misalignment

- Easy assembly and installation (pulleys do not need to be disassembled)

- High resistance to harsh environments

- Working temperature: -25°C / +80°C

Main Applications by Industry

Range

Z/3L, A/4L, B/5L, C.